Three researchers from The Johns Hopkins University have been awarded technology development grants totaling $240,000 from the Louis B. Thalheimer Fund for Translational Research.

In late May each year, finalists present their proposals virtually to a panel of independent researchers, investors, innovation executives and venture investors. The Thalheimer Fund, established with a generous $5.4 million donation from businessman and philanthropist Louis B. Thalheimer, provides seed funding for crucial proof-of-concept and validation studies at Johns Hopkins.

Since its inception in 2016, the Thalheimer Fund has awarded over $1.7 million to more than 20 projects at Johns Hopkins, with grants ranging from $25,000 to $100,000. All recipients have formally reported their inventions to JHTV. Last year’s winners included a cancer research team’s investigation into nanoparticles that can target a type of immune cell called CD4+ T cells, which play a crucial role in our body’s defense against diseases.

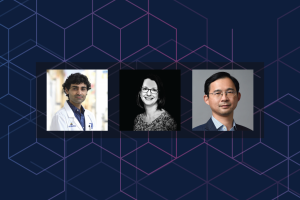

Reza Kalhor, Ph.D.

Assistant Professor, Biomedical Engineering, Molecular Biology and Genetics, joint appointment in Department of Medicine, Division of Molecular Medicine; Center for Epigenetics and Institute for Basic Biomedical Science

RESEARCH

A High-Throughput Cell Line Development Platform to Assess Cell Line Performance in Realistic Biomanufacturing Conditions

Kalhor has created significant advances in the field of cell line development. He has created a high-throughput screening platform using a technique called DNA barcoding.

Kalhor labels thousands of cells — specifically Chinese hamster ovary cells, which are commonly used in biomanufacturing — with unique DNA barcodes. These barcodes remain stable as the cells divide and multiply.

The goal is to track the behavior of these cells. By assessing their growth rate, productivity (in terms of producing antibodies or other useful molecules) and genetic stability, Kalhor aims to identify the most promising cell clones. The optimal clones can then be used for biomanufacturing purposes, such as producing vital drugs or vaccines.

Kalhor’s work combines biology, genetics and smart-labeling techniques to improve how we select the best cells for biomanufacturing. It’s an approach that holds great promise for advancing medical research and production.

Elizabeth (Betsy) Luczak, Ph.D.

Assistant Professor of Medicine, Johns Hopkins University School of Medicine;

Lab Manager, Mark E. Anderson Lab, Role of Excessive Mitchondrial CaMKII in Cardiomyopathy

RESEARCH

A Novel Drug Discovery Platform to Identify Small Molecules to Treat Atrial Fibrillation

Luczak has developed a method to identify druglike compounds for treating cardiac arrhythmias. The validation involved identifying an approved drug, ruxolitinib, which effectively prevents cardiac arrhythmias in mice, serving as a proof-of-concept.

The central focus is on the enzyme Ca2+ and calmodulin-dependent protein kinase II (CaMKII), a key player in abnormal rhythms associated with cardiovascular diseases. To measure CaMKII activity in living cells, the team introduced the CaMKII Activity Reporter (CaMKAR) — a highly specific and sensitive biosensor.

What sets CaMKAR apart is its ability to enable high-throughput compound discovery against CaMKII. This breakthrough technology addresses existing limitations and holds promise for advancing cardiac drug development. Despite the therapeutic potential of CaMKII inhibition, no clinically approved drugs currently target this enzyme. The CaMKAR biosensor represents a significant step toward transforming patient care in this critical area.

Chao Wang, Ph.D.

Ralph O’Connor Sustainable Energy Institute; Associate Professor, Department of Chemical and Biomolecular Engineering, The Johns Hopkins University

TECHNOLOGY

Electrochemical Extraction of Lithium from Seawater

Wang has pioneered a cost-effective method to extract lithium from seawater. While the ocean contains approximately 5,000 times more lithium than land does, its concentration is extremely low (around 0.2 parts per million). Wang’s innovative solution involves an electrochemical cell with a ceramic membrane made from lithium lanthanum titanium oxide. This membrane selectively allows lithium ions to pass through while blocking larger metal ions. By applying voltage, the cell drives lithium transport through the membrane, accumulating it in a separate chamber. The resulting lithium-enriched water can be used for battery manufacturing. This process costs just $5 of electricity to extract 1 kilogram of lithium from seawater. This method also produces valuable byproducts — hydrogen and chlorine — and the residual seawater can contribute to freshwater production in desalination plants.